Tomorrow the Horizon 2020 “GICO” project at the event for CCUS and alternative fuels entitled “Public perception and business models” supported by CINEA (European Climate, Infrastructure and Environment Executive Agency)!

IRIS has contributed to the development of an innovative 3D printing process falling within the “Direct Energy Deposition” (DED) methodology.

Learn moreIRIS evelops intelligent self-adaptive solutions for the efficient exploitation of laser processes: cutting, welding, direct metal deposition.

Learn moreIRIS develops atmospheric plasma processes for the treatment and functionalization of surfaces with different matrix.

Learn moreIRIS has conceived, designed and patented a treatment that allows any organic compound to be transformed into gas, separating it from any inert component, due to the high temperatures reached in the reaction chamber through the use of a thermal plasma system.

Learn moreIRIS, in addition to design AOP (Advanced Oxidation Process) systems for the recovery of wastewater and rainwater, has conceived, designed and patented the Waterplasma treatment that uses high voltage, but very short, electric impulses to treat fluid.

Lern moreIRIS collaborates with a team of architects, with whom it develops projects capable of merging together technological skills, functional, sociological and organizational aspects and developing indoor and outdoor spaces.

Learn moreIRIS has launched, through Walden srl, a project to promote the production of clean energy thanks to the use of biomass, obtained from sustainable forest management, which is accompanied by the spread of renewable energy, also.

Learn moreIRIS is the ideal interlocutor for who intend to design and implement innovative solutions based on the use of laser applications in industrial and “techno-rural” contexts.

Our Greenplasma on Elettronews!

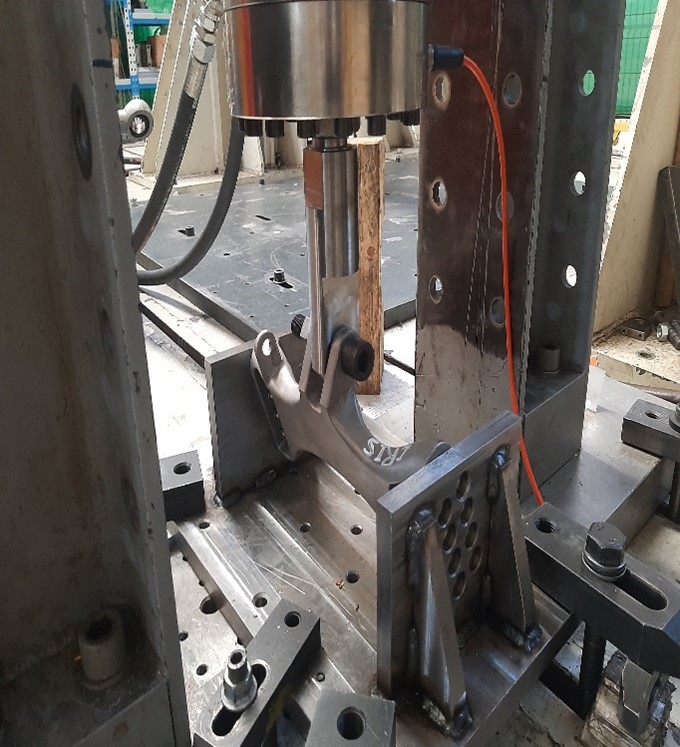

Have you ever seen a 3D printed finished metal component? We show it to you! In the photo, the titanium alloy actuator support manufactured in 3D at IRIS for the H2020 European LightMe project. The next photo shows the object after the CNC process at Coşkunöz Metal Form… and it passed all the mechanical tests too!