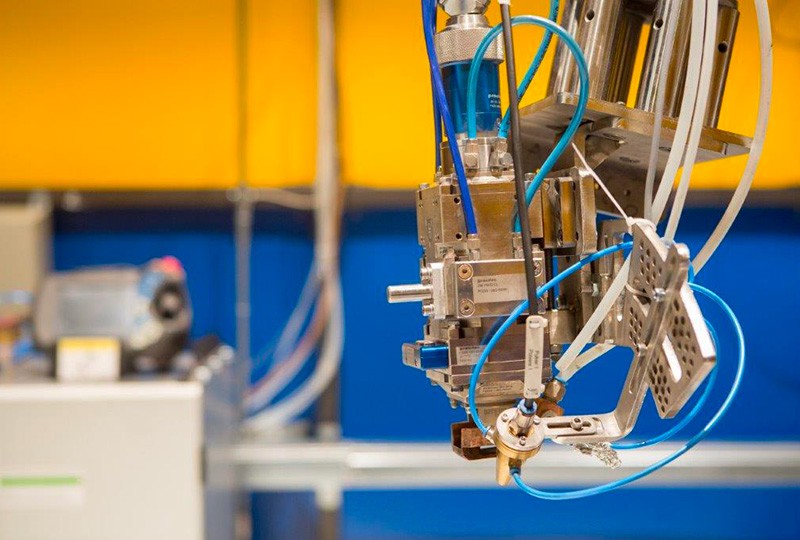

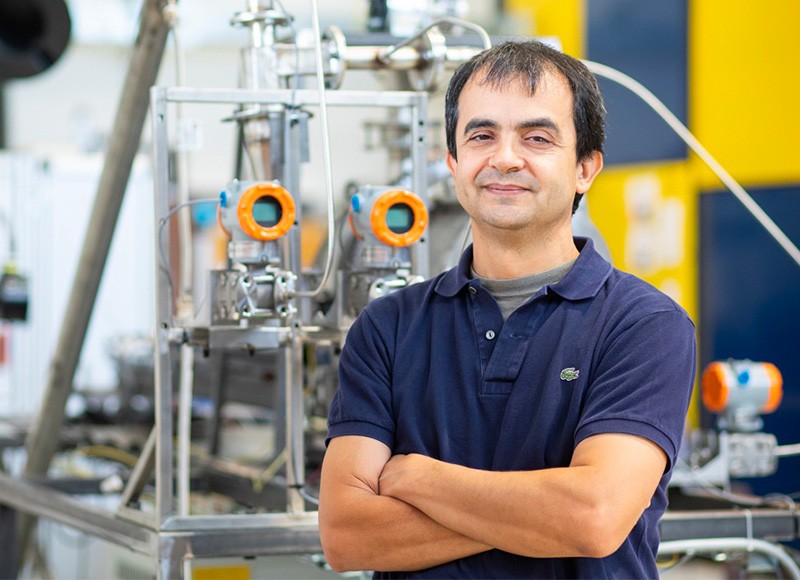

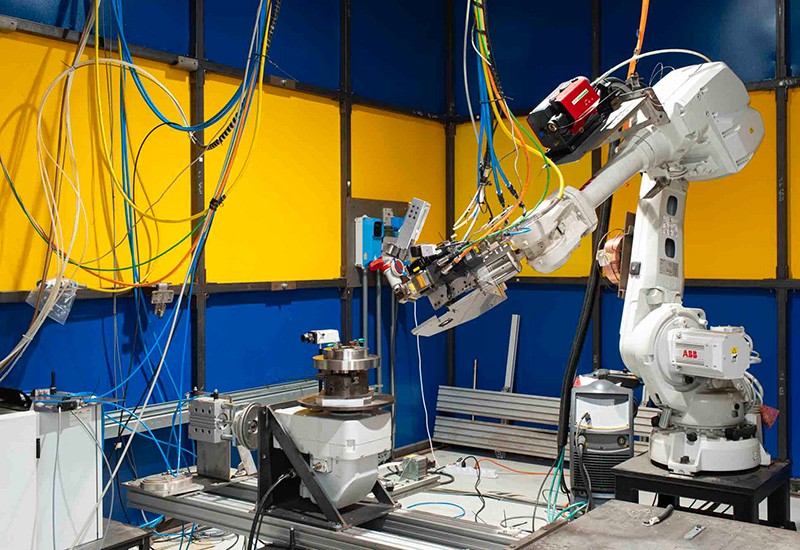

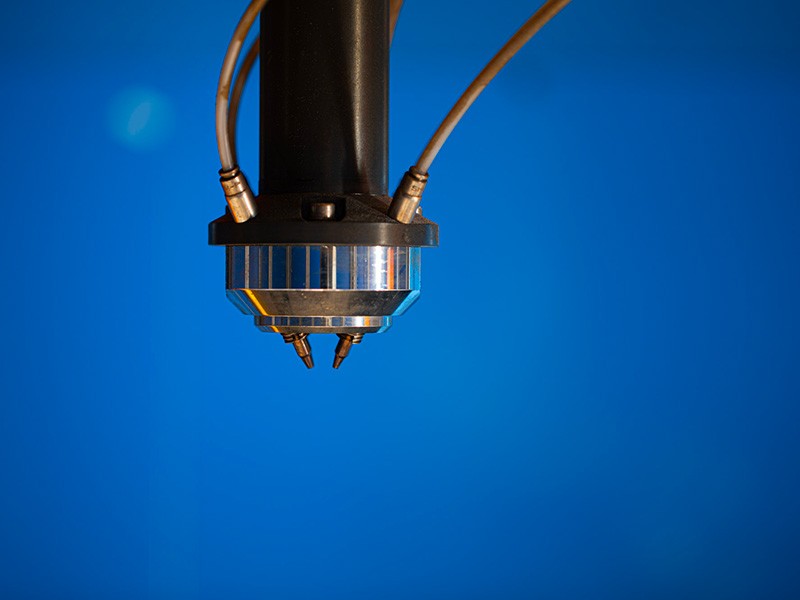

IRIS is part of a group of high-tech manufacturing SMEs headed by Laserlam, which has created a center specialized in laser, plasma, sheet metal processing, additives (both powder bed and DED) and 3D printing technologies.

Thanks to the sharing of know-how and skills within the group, IRIS is able to build technological demonstrator prototypes and test new processes/equipment in an industrial environment. The results of the process tests can be quickly sent to production, relying on the robust organizational and production structure of Laserlam, or to industrialization through the construction from scratch of the most suitable plant solution. Since October 2020, IRIS is Prima Open Additive Lab.

In the environmental field, IRIS supports and count on the collaboration of Walden, a technological start-up, born in 2019, active in the field of sustainable management/use of natural resources, the supply of forest products and the offer of renewable energy services and on Ambornetti, an entity created to start the recovery of an abandoned village through the creation of an eco-sustainable resort that will use the innovative technologies patented by IRIS.